The term “design-day” is used frequently in the HVAC industry, but it can have different meanings and is dependent on many factors. Design-day is typically used to describe a period of time with maximum conditions that a HVAC system was designed to accommodate and maintain the desired indoor temperature and humidity. These conditions can include weather, building occupancy, internal heat gains from people and equipment, and outdoor air ventilation rates. However, design-day is used most frequently in HVAC discussions to refer to climatic design conditions.

Design-day weather conditions are not necessarily fixed values. They are subjective and based on each specific design. Below are a number of standards and references that address the outdoor conditions a HVAC designer should use for their heating and cooling load calculations:

ASHRAE 183 – Peak Cooling and Heating Load Calculations in Building Except Low-Rise Residential Buildings

This ASHRAE Standard defines the procedures to calculate building heating and cooling loads and is referenced by the International Energy Conservation Code. It has the very subjective requirement that calculations “shall use values of outdoor air temperature and humidity for the building use, the building location, time of year, and time of day”. This reference requires the HVAC designer to determine the appropriate values.

ASHRAE Fundamentals – 2013, Chapter 14, Nonresidential Cooling and Heating Load Calculations

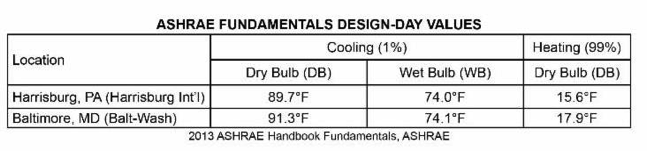

This heavily used reference includes extensive historical weather data for the U.S and other worldwide regions. ASHRAE recommends using design-day temperatures that are only exceeded, or lower than, the value 1% of the hours in the historical record. ASHRAE points out that if an HVAC system is designed for the most extreme annual conditions on record, the system could be grossly oversized. Oversized systems may not function efficiently and could have a higher initial cost than is necessary. Many facilities can accept the possibility of not maintaining design indoor conditions for a few hours a year to avoid these impacts. Some facilities, such as hospitals, may elect to use more extreme design-day values due to the critical nature of the spaces and functions occurring in the facility. As an example, ASHRAE’s recommends the following 1% design-day values:

If your facility is in these regions, you have probably experienced outdoor conditions beyond these design values.

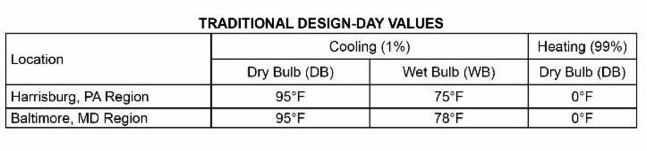

Traditionally Used Data

As noted above, ASHRAE Fundamentals recognizes that its published weather data does not provide an absolute maximum design condition and states that “design…temperatures may vary considerably from data traditionally used in various areas. “For that reason, many designers have established their own design-day values for various regions based on experience. The following table shows some traditional design-day values used by many engineers in the referenced regions:

Owner Requirements

In addition to published references, some owners have developed their own standard design conditions over time. Some large campus facility managers have developed multiple design-day conditions based on the criticality of the area being served by a HVAC system.

The determination of design-day conditions is subjective and there are many factors to consider. Owners should discuss their facility requirements with engineers at the start of the design process to ensure that the HVAC system meets their specific needs and expectations. If you need assistance in understanding more about design-day conditions or have questions for your next project, please do not hesitate to contact Douglas C. Barnhart, PE at (717) 845-7654 or dcb@ba-inc.com.