Digital Twins has been an industry buzzword being tossed around for a few years now, but what exactly is a Digital Twin? As with most new concepts, coalescing around a single definition can prove challenging. My own technical definition as it pertains to buildings and Architecture, Engineering, Construction and Operations (AECO) is:

‘A Digital Twin is a virtual representation of its built counterpart and contains spatial geometry and asset data that may be linked to real world sensors for real-time tracking of data which can be used in a variety of maintenance and predictive functions.’

In layman’s terms, that means a virtual model of a real building with data used to help operate and maintain the facility. The technical definition is a mouthful, so let’s break it down into smaller chunks.

As a virtual representation of a built asset, or a 3D digital model, a Digital Twin begins with a good design using BIM authoring software like Autodesk Revit. The design model, as the earliest stage of the digital twin, should capture the geometry reasonably accurately throughout both design and construction so that at project handover, there is a model available to the owner that contains all relevant spatial geometry of their building and the maintainable equipment, or assets, and associated systems inside. Asset data should include the asset name in the owner’s preferred format and its location in the building. It may contain additional information which can then be incorporated into the Digital Twin such as links to an O&M manual, manufacturer warranty, cut sheets or other external information.

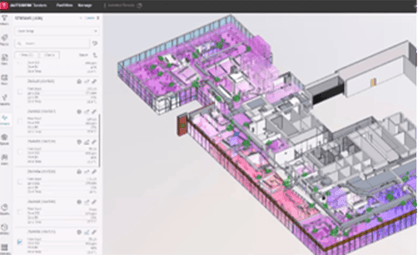

This BIM model is then incorporated into the Digital Twin software, such as Autodesk Tandem, a cloud-based platform designed for facility managers. By utilizing a cloud-based platform, the facility manager can have both a centralized view of their building on a laptop or PC, while allow allowing field personnel to access information from the Digital Twin on handheld devices such as an iPad or other tablet.

The second part of the Digital Twin is its capability to incorporate real world sensors and link them to assets inside the Digital Twin. This is where IoT (Internet of Things) comes into play. A simple example would be monitoring temperatures and humidity in rooms and linking that data back to the Digital Twin. By doing so, Facility Managers can monitor their building and set automatic alerts if a room’s temperature or humidity drifts outside of a set range. Other possibilities include lighting and lighting controls, CO2 monitoring, occupancy and much more.

Finally, what can a Facility Manager do with all that data at their fingertips? The AECO industry is currently only scratching the surface of what is possible. The industry is moving from Descriptive Twins (the virtual representation of the building and its assets, the 3D digital model) into Informative Twins (incorporating data and sensors). Current common uses include scheduling maintenance, monitoring downtimes, and identifying potential issues prior to a user complaint. Incorporating Building Automation Systems into asset management creates opportunities to track operational costs, identify maintenance opportunities and result in more facility uptime. In coming years, the data accumulated will lead to Predictive Twins which will predict maintenance needs and will integrate AI to make recommendations to Facility Managers.

The overall goal is to provide a single source of truth to facility managers that is easily accessible, intuitive to use, and can be easily updated with changes throughout the life of the building.

A key first step on a Digital Twin journey is to determine what data and reporting would be useful to the Facility Manager. Having too much data that is superfluous can be overwhelming and cause one to lose sight of what is essential. The next step is to decide how the Owner wants to organize and use that data and select a platform that will provide that solution. Finally, communication with the Design Team at an early stage and development of a plan to capture and deliver what is needed is essential. While incorporating a Digital Twin has a cost, the return of running an energy efficient building that is well maintained and minimizes repairs and downtime can offset the software and integration cost over the lifetime of the building.

If you or your project team could benefit from an in-depth look at Digital Twins, please reach out to Barton’s Director of BIM/VDC, Ken McLain at km@ba-inc.com or 814-237-2180.